Tugger winches play a crucial role in maritime operations, facilitating the movement of cargo, equipment, and supplies on commercial vessels and offshore platforms. As the maritime industry faces increasing scrutiny and regulations regarding environmental impact, the design and operation of tugger winches are evolving to minimize their ecological footprint. This article examines the environmental considerations involved in tugger winch design and operations, highlighting current practices and future trends.

Energy Efficiency

Electric vs. Hydraulic Systems

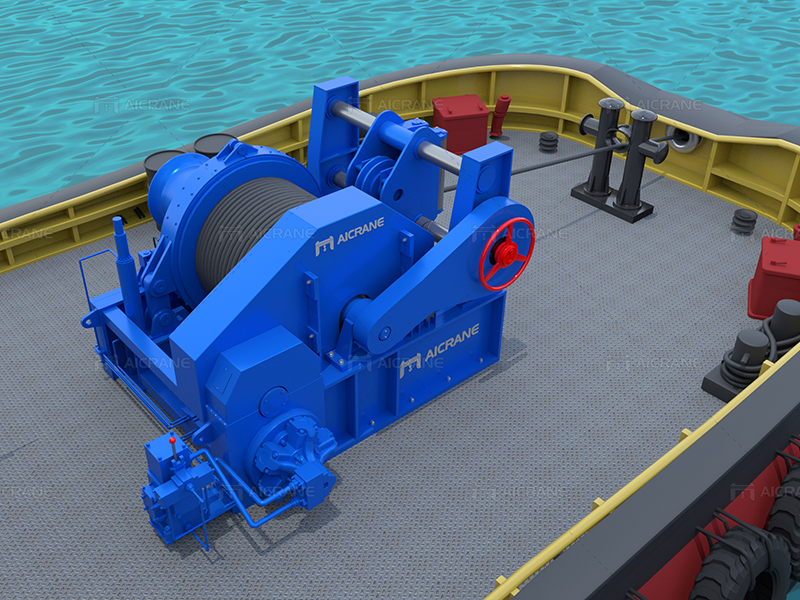

The choice between electric and hydraulic tugger winch systems significantly impacts energy efficiency and environmental sustainability:

Electric Winches: Electric winches are gaining popularity due to their higher efficiency and reduced emissions compared to traditional hydraulic systems. They utilize onboard electrical power or batteries, minimizing reliance on fossil fuels and lowering carbon footprint.

Hydraulic Winches: While hydraulic winches remain robust for heavy-duty applications, advancements in hydraulic technology aim to improve efficiency and reduce energy consumption. However, hydraulic systems typically require hydraulic fluid, which raises concerns about leakage and environmental impact if not managed properly.

Material Selection and Durability

Lightweight Materials

Selecting lightweight, corrosion-resistant materials for tugger winch construction contributes to fuel efficiency and reduces environmental impact:

Aluminum and Composites: These materials offer high strength-to-weight ratios, enhancing winch performance while lowering overall vessel weight. Reduced weight translates to lower fuel consumption and emissions during operation.

Corrosion Resistance: Implementing corrosion-resistant coatings or materials prolongs winch lifespan and reduces maintenance requirements, minimizing the use of chemicals and resources over time.

Noise and Emissions Control

Noise Reduction

Noise pollution from tugger winch operations can disturb marine life and impact nearby communities:

Noise Dampening Technologies: Integrating noise reduction measures such as insulation and vibration dampeners into winch design mitigates sound propagation. This ensures compliance with environmental regulations and promotes a quieter operating environment.

Emission Mitigation

Minimizing exhaust emissions during tugger winch operation is critical for reducing the vessel’s environmental footprint:

Emission Control Systems: Implementing exhaust gas scrubbers or catalytic converters helps reduce harmful pollutants released into the atmosphere. These systems improve air quality and align with stringent emission standards in coastal and port areas.

Waste Management and Sustainability

Fluid Management

Proper management of hydraulic fluids and lubricants is essential for environmental sustainability:

Spill Prevention: Implementing spill containment systems and regular inspections minimize the risk of fluid leaks into marine environments. Prompt detection and response to leaks mitigate potential ecological damage.

Sustainable Practices

Adopting sustainable practices in hydraulic and electric tugger winch operations promotes environmental stewardship:

Waste Reduction: Implementing practices to reduce waste generation and promote recycling of materials used in winch maintenance and operation.

Compliance and Regulatory Considerations

Regulatory Compliance

Staying abreast of evolving environmental regulations is crucial for ensuring tugger winch operations meet compliance standards:

International Maritime Organization (IMO): Compliance with IMO regulations, such as MARPOL Annex VI on air pollution from ships, requires vessels to minimize emissions through efficient equipment and operational practices.

Local Regulations: Adherence to local environmental regulations in ports and coastal regions ensures seamless operations without incurring penalties or restrictions.

Industry Initiatives and Future Outlook

Green Technologies

Continued research and development focus on green technologies for tugger winches:

Electric-Hybrid Systems: Advancements in electric-hybrid tugger winch systems combine the benefits of electric power with the robustness of hydraulic systems, offering enhanced efficiency and reduced environmental impact.

Smart Technology Integration: Integration of smart sensors and predictive maintenance systems optimize tugger winch machine performance while minimizing energy consumption and environmental footprint.

Environmental considerations are increasingly shaping the design, operation, and future innovations of tugger winches in the maritime industry. By prioritizing energy efficiency, material sustainability, emissions control, and regulatory compliance, maritime operators can mitigate environmental impact while maintaining operational efficiency. Embracing green technologies and sustainable practices not only enhances environmental stewardship but also positions the maritime industry for long-term sustainability and resilience in a rapidly evolving regulatory landscape.